The main reason for the use of a 2-stroke engine is it accelerates much faster than a similarly sized 4-stroke engine. The obvious reason for this is a 2-stroke cylinder fires on every revolution of the crank shaft, while a 4-stroke does it every other revolution. Also because the 2-stroke fires on every revolution, they only need enough weight to balance the engine. A 4-stroke engine needs added weight in the crank shaft to allow it to keep running during the non-firing stroke. This applies mainly when the engine is running in the lower RPM ranges. Due to the added weight, it takes the engine longer to increase speed from the lower to higher RPM ranges.

These engines are also primarily air cooled. Having a single cylinder engine air cooled is a lot more efficient than trying to cool a two (or more) cylinder air-cooled engine. Air cooled is a simpler solution than is water cooled.

A single cylinder engine is a lot simpler than a two cylinder engine, whether 2- or 4-stroke. There are just a lot less moving parts.

There is no issue with why larger is better ... it goes back to the old saying of There is no replacement for displacement. Having more displacement, whether 2- or 4-stroke is going to provide more low end torque.

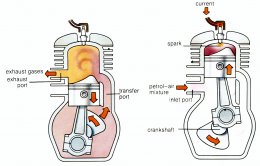

Due to the way most 2-strokes fill the cylinder with air/fuel mixture, they are inherently less efficient than a 4-stroke engine is. The volumetric efficiency of a naturally aspirated 2-stroke limits its ability to make power. A similarly sized 4-stroke can fill the cylinder a lot more completely, allowing it to make a lot more power. For the edification of those who may not know, a 2-stroke engine only has a reed valve which functions as a check valve to allow for the correct air/exhaust flow. The inlet for the air/fuel is through low in the cylinder port(s) on one side of the cylinder. These inlets are at the position where, as the piston travels down in the cylinder, these ports are uncovered to allow the air/fuel mixture to enter the cylinder. As the piston travels back up the cylinder, the port(s) are closed off, which allows for the compression of the air/fuel mixture just prior to ignition. As the piston travels down the cylinder, it gets to the exhaust port(s) first, which are also in the side of the cylinder, only opposite the intake ports. The pistons are usually specifically shaped to direct the outgoing exhaust and incoming air/fuel mixture in the correct direction so the engine will actually function (instead of say the exhaust going out the intake port). In comparison, a 4-stroke piston is relatively flat (there are exceptions). Here's a pretty good representation of the two strokes and piston shape:

With a dirt bike, having the low end torque you need to dig your way out of a tight turn, then having the ability to get up to speed quickly ... that's where it's at. A 2-stroke engine can do both of these for a bike, at the cost of efficiency in the process.

RELATED VIDEO