This answer, by no means, replaces Walters. However, another important reason that engines drop in efficiency as RPM increases is because we design them that way. Engines are just big optimized air pumps, and the efficiency throughout the RPM range is something that has been tackled in many different ways.

This answer, by no means, replaces Walters. However, another important reason that engines drop in efficiency as RPM increases is because we design them that way. Engines are just big optimized air pumps, and the efficiency throughout the RPM range is something that has been tackled in many different ways.

Below is an explanation from another answer I wrote that may help:

Mathematically speaking, we need torque and RPM to make horsepower.

As you can see, we need rpm to get horsepower. But that is only half of the equation. And it is the obvious half. RPM is just rotations per a minute. If the bridge from rpm to horsepower, torque, was constant that would mean that we could make horsepower go to infinity... IF torque was constant. However, that is not the case.

The fact is, we cannot make our torque output constant. Although we do try.

The fact is, we cannot make our torque output constant. Although we do try.

Here is a basic dyno sheet (graph showing the horsepower and torque produced by a car per engine RPM).

Pretty far from constant huh? Engines don't have that constant torque delivery for a several reasons, but one major factor is air flow optimization. Our engines are just big, optimized, air pumps. The more efficiently you can pump the air through, the more power you get. The problem is that we are stuck with certain constraints that force us to pick at what RPM we want the motor to run the most efficiently.

Have you heard the sound of a big American muscle car at idle? The motor sounds choppy, and powerful sounding. But if you really think about, it doesn't sound like it is running very smooth does it?

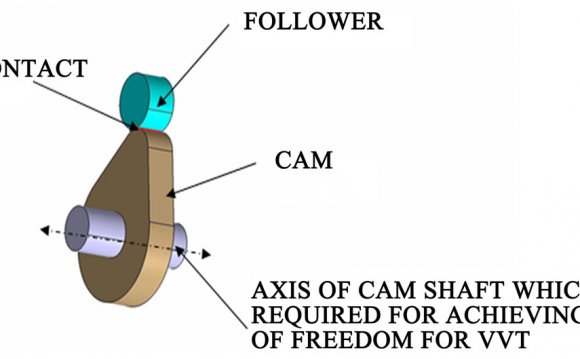

Well, if you think it sounds like it is running rough, it is because it is. The reason for this is because the car has been modified to have a different cam timing/lift/etc that is optimized for higher RPM. Thus making it barely run at lower idle RPM. Have you ever heard "the VTEC just kicked in yo!"? VTEC, aka Variable Valve Timing, is actually Hondas work around to this optimization problem. Instead of the engine having just one cam for the whole rpm range it has three! Okay, it doesn't actually have three, it has three cam lobes for each valve. You get the point, so the engine has a more optimized working range.

Have you ever heard "the VTEC just kicked in yo!"? VTEC, aka Variable Valve Timing, is actually Hondas work around to this optimization problem. Instead of the engine having just one cam for the whole rpm range it has three! Okay, it doesn't actually have three, it has three cam lobes for each valve. You get the point, so the engine has a more optimized working range.

Toyota uses another method where they just change cam advance called VVTi. It is not able to control as many cam variables, but it is analog instead of the digital switching of the Honda system.

Other methods have been used to flatten out the horsepower curve and optimize flow throughout the RPM range. Nissan just used the equivalent of two intake manifolds with different length runners, and had a baffle that switched between them. Other advances have been being implemented with these concepts from companies like Audi.

This method gives us another dyno graph that shows the same kind of results:

RELATED VIDEO